Xtreme Lift Wide Selection Of Press Brake Tools Wilson Tool

These tools are made to extraordinarily tight tolerances. Tooling Types. The industry's tools are classified in several general categories, including American tools, European-style tools, New Standard tools, and others. One difference between them is how the tools mount to the press brake, as well as how bending force flows through them.

Press Brake Press Brake Tooling

Press Brake Tooling. Mate has an extensive product line of press brake tooling including American Precision Style with Maglock® magnetic safety system, European Precision Style, and Wila Trumpf Style. Mate's product line includes punches, press brake dies, standard specials, specials and accessories manufactured from premium alloy tool steels.

The 3 Types of Bending in Press Brakes

AMADA tooling is hardened and precision ground to give you optimal press brake performance with all critical tolerances within ± 0.0008" (.02mm). AMADA precision performance helps eliminate secondary handling to correct errors while also helping to decrease bending costs. In addition, AMADA tooling is through-hardened, providing you with long.

Custom press brake tooling available from Mate Precision Tooling

Overview. Mate's American Precision Style press brake tooling is a full line of precision ground punches and dies. This system has the widest options available for common height punches and dies, along with an industry-first option to purchase by the inch—just specify and buy the tooling length required for your design.. All Mate American Precision Style punches come standard with our.

Press Brake Punch Mold and Die Tools , Amada Press brake tooling

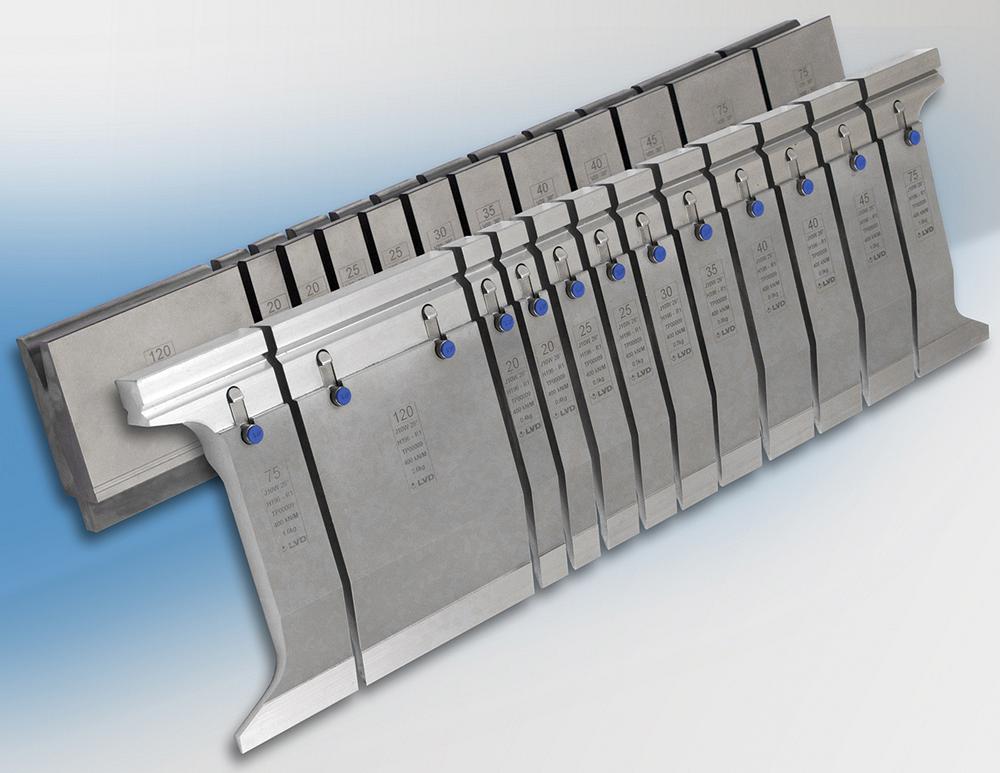

A complete line of standard press brake tooling is available for machines from 120 to 30000 kN. Single, multiple and adjustable V-dies, vertical removable style tooling and special tooling for custom applications. Robotized press brakes. Stand-alone press brakes.

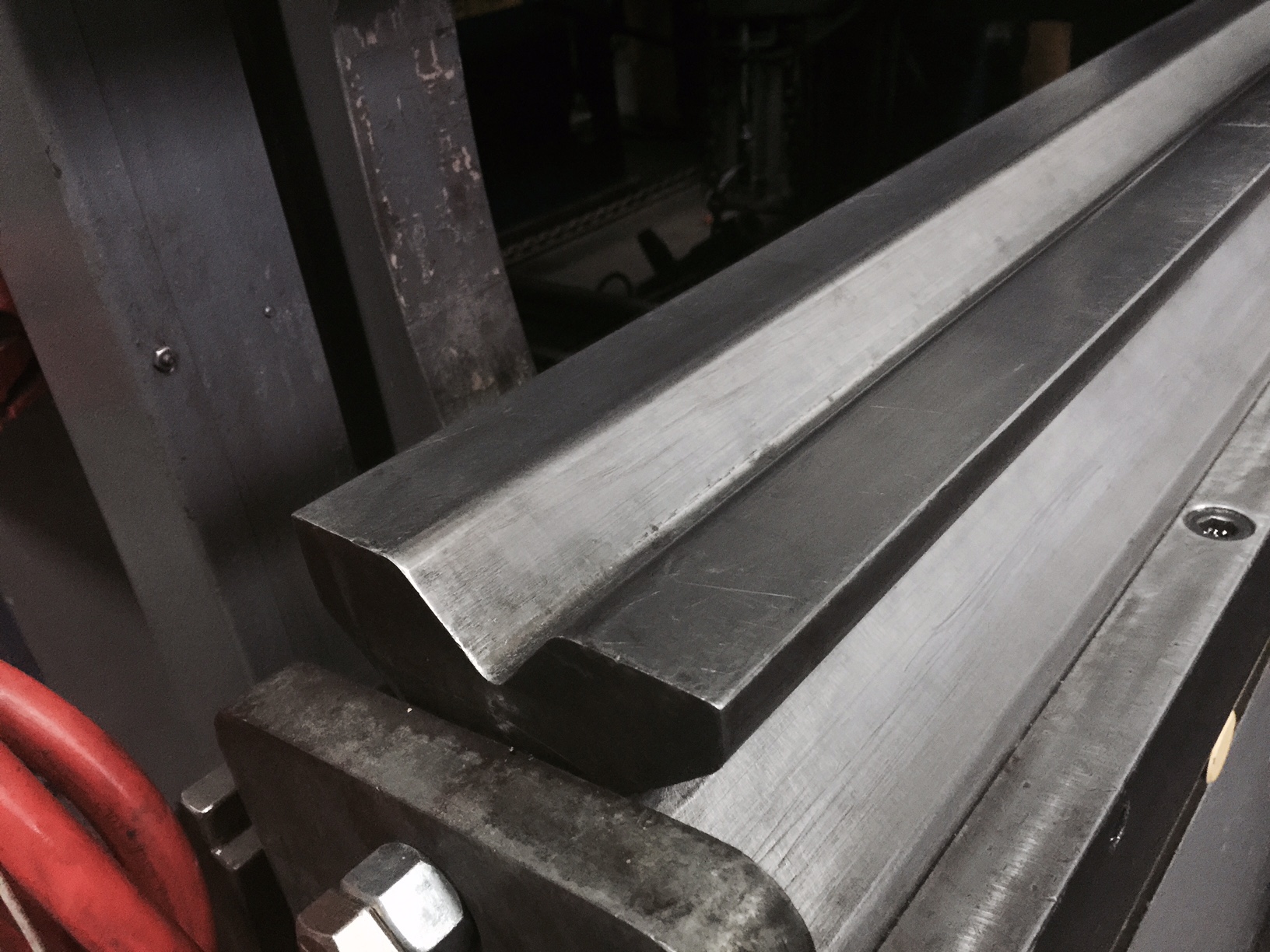

Extend press brake tooling life

AE Tooling is a renowned provider of press brake tooling that plays a crucial role in the fabrication of sheet materials worldwide. Our press brake tooling consists of a range of components, with different molds necessary for creating specific parts. Ultimately, our tooling enables the production of precisely shaped steel items. As industry.

Heavy Duty Press Brake Tool, Press Brake Tooling, प्रेस ब्रेक टूल, प्रेस ब्रेक के उपकरण

Looking For Brake Press -tooling? We Have Almost Everything On eBay. But Did You Check eBay? Check Out Brake Press -tooling On eBay.

Easy DIY Guide to Press Brakes [ Tooling, Metal Folding, Magnabend ] CNCCookbook Be A Better

Check our online Press Brake Tooling quotation form to request quote or call us today at +1 (416) 751-1901 to find out more information about press brake tooling for. Notes: The tonnages indicated in bold italics are for die openings eight times the thickness of the metal. With an 8:1 die ratio, the inside radius of a right angle bend is.

CNC press brake tooling gets organised

Bending Solutions to solve common to complex forming problems. Leading the way to your fabricating success since 1969. Quality and value supplier of all makes and models of Press Brake Tooling

How to properly maintain press brake tooling

American style pRESS bRAKE TOOLING in stock note: THESE IN STOCK TOOLS LISTED BELOW are at discounted prices. THE SECTIONS CAN NOT BE USED TOGETHER TO MAKE LONGER LENGTHS DUE TO THEY WERE NOT MADE TOGETHER. If this is needed, please contact us. thank you. D14. 40" = $187.00. 46" = $197.00. 53" = $227.00.

Easy DIY Guide to Press Brakes [ Tooling, Metal Folding, Magnabend ] CNCCookbook Be A Better

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to precisely position.

Press Brake Tooling Designed in LVD Style

Press brake tooling is an essential component of press brake machines that helps to ensure the accuracy and quality of the final bent parts. It is composed of a punch and a die that are used to shape and bend metal sheets or plates into the desired shape.

Developing a Press Brake Tooling Case Study Highland Machine

With tooling and clamping solutions geared toward decreasing press brake setup times, speeding part flow and optimizing part quality, press brake tooling from Wilson Tool International combines state-of-the-art manufacturing with groundbreaking innovation. See below for recent products and solutions geared toward optimizing productivity on the.

Edwards 32" Press Brake Tooling Norman Machine Tool

Currently, steel is the most widely used material for producing press brake tools, including T8 steel, T10 steel, 42CrMo, and Cr12MoV. 42CrMo is a high-strength alloy steel that has undergone quenching and tempering to display high strength and toughness.. It can operate at low temperatures down to -500°C and is known for its high strength, toughness, and resistance to wear.

Special Shapes Forming Press Brake Tooling China Press Brake Tooling and Press Brake Die

Press Brake Tooling. Press brake tooling makes all the difference when choosing a manufacturer for metalworks. A variety of tools, along with the machinery's tonnage, determines production flexibility. Tooling both enables and limits production. If you make something out of the ordinary, there's a good chance that special tooling is needed.

Used Press Brake Tooling Many Types And Sizes Sanson Machinery Group

Press Brake Tooling. Mate has an extensive product line of American Precision Style with the Maglock® magnetic safety system, European Precision Style, and Wila Trumpf Style. Mate's product line includes punches, press brake dies, standard specials, specials and accessories manufactured from premium alloy tool steels.